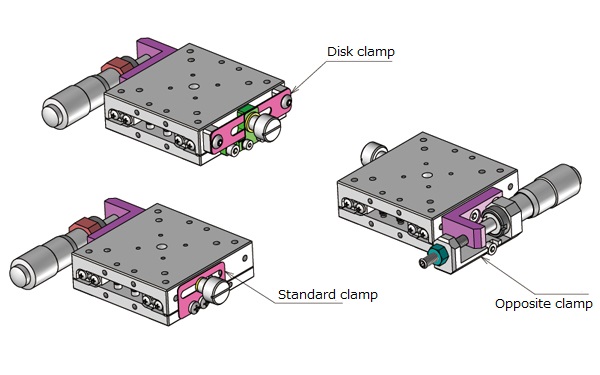

Clamp (stopper)

- What's the difference between clamps (standard, disk, opposite)?

- There are 3 types of clamp methods (standard, disk, opposite). What kind of features do they have?

-

◆ Standard clamp

Tighten the clamp knob, then push and fix the clamp plate on the side of stage by using resin ring.

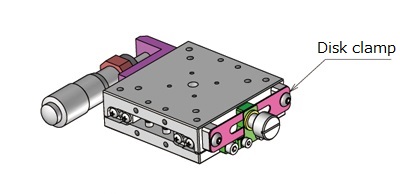

◆ Disk clamp

Fix the disk attached to the side of the stage by tightening the clamp knob.

The load on the stage body can be reduced, and it is possible to suppress the gap when fixed.

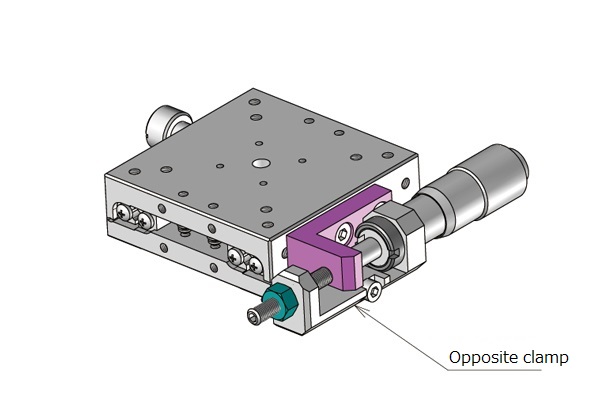

◆ Opposite clamp

Press the bolt from the opposite direction of the micrometer. In order to prevent further loosening

with a nut, a large fixing force can be obtained.

- Countermeasures when the clamp is loosened by vibration

- Currently we use standard clamp products (eg BSS16-60C).

The vibration of the device loosens the clamp. Can we take any countermeasures? -

There is a clamp option called "opposite clamp".

It presses the bolt from the opposite direction of the micrometer (or feed screw).

Furthermore, a large fixing force can be obtained because the nut is used to prevent loosening.

* The holding power is improved, and the looseness can be reduced.

- I want to reduce the gap when tightening the clamp

- The stage is used to adjust the initial position of the CCD camera.

After adjustment of initial position, it goes out of position when tightening the clamp. Can we take

any countermeasures? -

There is a clamp option called "disk clamp".

Fix the disk attached to the side of the stage by tightening the clamp knob.

The load on the stage body can be reduced, and it is possible to suppress the gap when fixed.

- Manual rotation stage moves after clamped

- I use a manual rotation stage. After positioning, it will move even if the clamp on the opposite part

of the micrometer is tightened ... Is the usage correct? -

Our manual rotary stage is designed to enable fine adjustment after coarse positioning.

The coarse clamp must be tightened first. Specifically, the procedure is as follows.

1. Coarse adjustment with the feed knob to the desired position (the knob turns 360 degrees)

2. Tighten and fix the coarse clamp

3. Fine adjustment with a micrometer to the desired position

4. Tighten and fix the micromotion clamp